SEQUENZIELL-MANUELLES-GETRIEBE WIKI

ZUSÄTZLICHE INFORMATIONEN

Der 12V Gleichstrommotor treibt die hydraulische Außenzahnradpumpe der Hydraulikeinheit an und wird über das SMG Relais angesteuert, sobald der minimale Grenzwert für den Hydraulikdruck erreicht wird. Dieser, sowie der maximale Druckwert für die Abschaltung des Elektromotors sind flexibel und immer abhängig von der Temperatur des Hydrauliköls. Je wärmer die Hydrauliktemperatur, desto höher ist der Abschaltdruck für die Pumpe.

Das Druckbegrenzungsventil ist in der Hydraulikeinheit verbaut und dient als Sicherheitselement für das Gesamtsystem. Sollte durch einen Defekt der Druck auf 100 bar steigen, dann öffnet das Ventil und verbindet Saug- und Druckseite der Hydraulikpumpe.

Zur Überwachung der Hydrauliktemperatur ist ein NTC-Temperatursensor in der Hydraulikeinheit verbaut. (-30 °C -> 26114 Ω; 130 °C -> 89 Ω)

Zur Überwachung des Hydraulikdrucks ist ein Drucksensor in der Hydraulikeinheit verbaut. (0,5 V -> 0 bar; 4,58 V -> 100 bar)

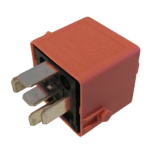

SMG-Relais

Das lachsfarbene Relais in der Steuergerätbox wird vom SMG-Steuergerät geschalten und steuert den Elektromotor an. Das Relais bleibt mit der Zeit hängen und sollte dann ersetzt werden.

Der Kolbenspeicher dient im SMG-Hydrauliksystem als Mediumspeicher. Im Druckspeicher trennt ein Kolben die Stickstofffüllung vom Hydrauliköl. Der Vorspanndruck der Füllung beträgt im Neuzustand knapp 39 bar. Mit zunehmendem Alter verliert die Vorspannung Ihren Druck. Fällt diese unter 29 bar, dann muss der Kolbenspeicher getauscht werden.

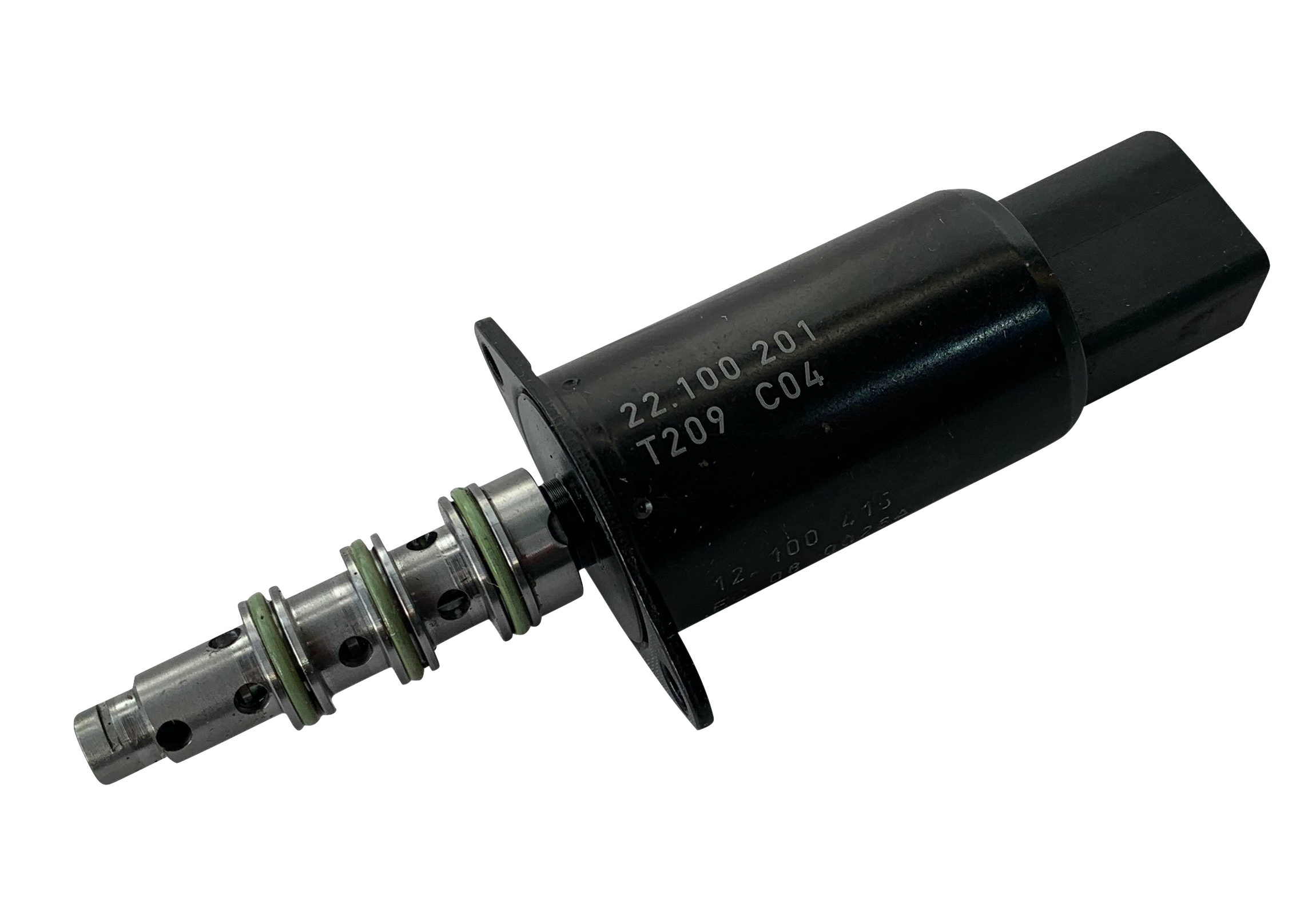

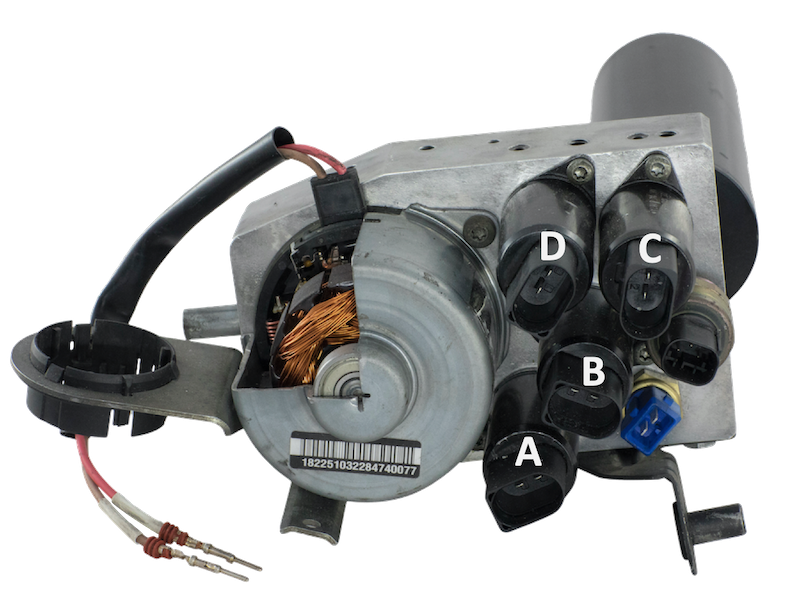

Übersicht Magnetventile

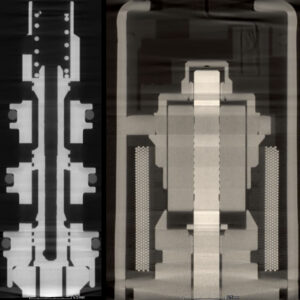

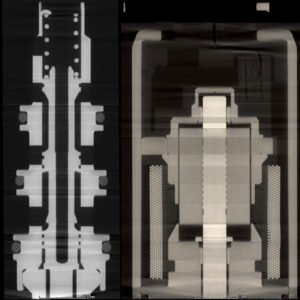

Proportional-Druckregelventil (Gang 1, 3, 5 (A); Gang 2, 4, 6 (D))

Die beiden Proportional-Druckregelventile versorgen jeweils eine Seite des Schaltweg-Zylinders mit Hydrauliköl. Für die Vor- und Rückbewegung wird jeweils eine Kolbenseite über ein Magnetventil mit Druck versorgt und über das andere Magnetventil wird das verdrängte Volumen der gegenüberliegenden Kolbenseite zur Tank in der Hydraulikeinheit zurückgeführt.

Proportional-Wegeventil (Kupplung (B); Wählwinkel (C))

Die beiden Proportinal-Wegeventile in der Hydraulikeinheit versorgen den Nehmerzlinder der Kupplung und den Zylinder für den Wählwinkel mit Hydrauliköl. Es gibt drei Stellungen:

- Druckreduzierung: Es gibt Kupplungsvorgang oder Gangwechsel. Beide Zylinder sind direkt mit dem Öltank verbunden.

- Druckaufbau: Gibt es einen Kupplungsvorgang oder ein Gang soll geschaltet werden, dann wird Hydrauliköl aus dem Kolbenspeicher in die Zylinder geleitet. Die Magnetventile benötigen hier knapp 1,1 bis 2 Ampere.

- Druck halten: Wenn Ausgekuppelt ist oder die Schaltwelle ihre Position erreicht hat, wird der Öldruck in den beiden Zylindern gehalten.

| Fehlercode | Fehlerbezeichnung | mögliche Ursache | Maßnahmen |

| 16 (0x10) | Ansteuerung Magnetventil Schaltweg Vor |

|

|

| 17 (0x11) | Ansteuerung Magnetventil Schaltweg Rueck |

|

|

| 18 (0x12) | Ansteuerung Magnetventil Waehlwinkel |

|

|

| 19 (0x13) | Ansteuerung Shift Lock |

|

|

| 20 (0x14) | Anlasserfreigabe |

|

|

| 21 (0x15) | Relais Hydraulikpumpe |

|

|

| 22 (0x16) | Ansteuerung Rueckfahrtlichtschalter |

|

|

| 23 (0x17) | Ansteuerung Magnetventil Kupplung |

|

|

| 32 (0x20) | Auswertung Getriebeeingangsdrehzahl |

|

|

| 33 (0x21) | Auswertung Motordrehzahl (Sensor) |

|

|

| 34 (0x22) | Getriebetemperatur |

|

|

| 35 (0x23) | Auswertung Hydraulikdrucksensor |

|

|

| 36 (0x24) | Auswertung Positionsgeber Waehlwinkel |

|

|

| 37 (0x25) | Auswertung Positionsgeber Schaltweg |

|

|

| 38 (0x26) | Auswertung Laengsbeschleunigung |

|

|

| 39 (0x27) | Hydrauliktemperatur |

|

|

| 40 (0x28) | Auswertung PLCD-Sensor fuer Kupplungsposition |

|

|

| 48 (0x30) | Gang nicht einlegbar |

|

|

| 49 (0x31) | Gangspringer |

|

|

| 50 (0x32) | Waehlwinkel nicht einregelbar |

|

|

| 51 (0x33) | Auswertung Motorhaubenkontakt im Fahrbetrieb |

|

|

| 52 (0x34) | Auswertung Motorhaubenkontakt im Stand |

|

|

| 53 (0x35) | Druckbandunterschreitung HE |

|

|

| 54 (0x36) | Druckbandüberschreitung HE |

|

|

| 55 (0x37) | Einschalthäufigkeit Hydraulikeinheit |

|

|

| 56 (0x38) | Einschaltdauer Hydraulikeinheit |

|

|

| 57 (0x39) | Missbrauch Hydraulikeinheit |

|

|

| 58 (0x3A) | Gang nicht auslegbar |

|

|

| 59 (0x3B) | Ansteuerung Kupplung |

|

|

| 80 (0x50) | SMG Steuergeraet interner Fehler |

|

|

| 81 (0x51) | Auswertung ESTATE | ||

| 83 (0x53) | Getriebeadaption |

|

|

| 84 (0x54) | Allgemeine Adaption |

|

|

| 85 (0x55) | Adaption der Kupplung |

|

|

| 86 (0x56) | Entlueftungen | ||

| 87 (0x57) | Aktionsmodi | ||

| 88 (0x58) | Adaptionswerte Getriebe | ||

| 97 (0x61) | Spannungsversorgung |

|

|

| 98 (0x62) | Sensorspannungsversorgung A |

|

|

| 99 (0x63) | Sensorspannungsversorgung B |

|

|

| 100 (0x64) | Spannungsversorgung Magnetventile Schaltweg |

|

|

| 101 (0x65) | Spannungsversorgung Magnetventile Kupplung und Waehlwinkel |

|

|

| 114 (0x72) | Auswertung Waehlhebel |

|

|

| 115 (0x73) | Auswertung Verbraucherabschaltung VA | ||

| 116 (0x74) | Auswertung Programmwahlschalter Plus | ||

| 117 (0x75) | Auswertung Programmwahlschalter Minus | ||

| 118 (0x76) | Auswertung Lenkradschalter + | ||

| 119 (0x77) | Auswertung Lenkradschalter – | ||

| 120 (0x78) | Auswertung Zuendschlosssignal | ||

| 128 (0x80) | Fehlerhafte CAN-Botschaft / CAN Busfehler |

|

|

| 129 (0x81) | CAN-Fehler |

|

|

| 144 (0x90) | Auswertung Tuerkontakt ueber CAN |

|

|

| 145 (0x91) | Auswertung Geschwindigkeit hinten links |

|

|

| 146 (0x92) | Auswertung Geschwindigkeit hinten rechts |

|

|

| 147 (0x93) | Auswertung Geschwindigkeit vorne links |

|

|

| 148 (0x94) | Auswertung Geschwindgikeit vorne rechts |

|

|

| 149 (0x95) | Auswertung Geschwindigkeiten (mehr als ein Signal) |

|

|

| 150 (0x96) | Auswertung Motordrehzahl (CAN) |

|

|

| 151 (0x97) | Auswertung Betriebsbremssignale ueber CAN |

|

|

| 152 (0x98) | Auswertung Lenkwinkel ueber CAN |

|

|

| 153 (0x99) | Auswertung Querbeschleunigung ueber CAN |

|

|

| 154 (0x9A) | Auswertungs Laengsbeschleunigung ueber CAN |

|

|

| 155 (0x9B) | Auswertung Fahrpedalwert ueber CAN |

|

|

| 176 (0xB0) | Sicherheitskonzept Ebene 2 Getriebe | ||

| 177 (0xB1) | Sicherheitskonzept Ebene 2 Kupplung | ||

| 178 (0xB2) | Sicherheitskonzept Ebene 3 | ||

| 179 (0xB3) | Sicherheitskonzept Ebene 2 RAM | ||

| 180 (0xB4) | Sicherheitskonzept Ebene 2 INPUT | ||

| 255 (0xFF) | unbekannter Fehlerort |

| Pin Stecker | Bezeichnung | Kabelfarbe |

| 1 | – | – |

| 2 | Drucksensor + | grün weiß |

| 3 | Temperatursensor – | braun |

| 4 | Drucksensor – | braun |

| 5 | Temperatursensor + | weiß |

| 6 | Drucksensor Signal | orange |

| 7 | – | – |

| 8 | E-Motor – | braun |

| 9 | Ventil Kupplung (B) | rot weiß |

| 10 | Ventil Kupplung (B) | gelb |

| 11 | E-Motor + | rot gelb |

| 12 | Ventil Wählwinkel (C) | schwarz gelb |

| 13 | Ventil Wählwinkel (C) | schwarz rot |

| 14 | Ventil Gang 2, 4, 6 (D) | schwarz weiß |

| 15 | Ventil Gang 2, 4, 6 (D) | schwarz violett |

| 16 | Ventil Gang 1, 3, 5 (A) | blau |

| 17 | Ventil Gang 1, 3, 5 (A) | schwarz blau |

| 18 | – | – |